MECHANICAL ENGINEERING

IMPLEMENTING YOUR

TECHNOLOGICAL

EXCELLENCE

We collaboratively design and engineer futuristic products and solutions, optimise existing ones and significantly improve the design engineering cycle time. We have multi domain expertise across over 2200 projects, many of them complex engineering assignments. We integrate mechanical with digital.

SERVICES WE OFFER

PRODUCT DESIGN ENGINEERING & DEVELOPMENT

PRODUCT LOCALIZATION & IMPROVISATIO

VALUE / KNOWLEDGE BASED ENGINEERING

MACHINERY DESIGN & REVERSE ENGINEERING

STYLING & RENDERING

DESIGN AUTOMATION & CAD CUSTOMIZATION

FLUID ENGINEERING (FLUID DYNAMICS)

DRAFTING & DETAILED ENGINEERING

LEGACY DATA CONVERSION (MIGRATION)

PLM (CHANGE MANAGEMENT)

TESTING & VALIDATION OR ANALYSIS & SIMULATION

SOFTWARES

DESIGN

AUTOCAD

INVENTOR

SIEMENS NX

CREO

SOLIDWORKS

SOLIDEDGE

CATIA

ANALYSIS

ANSYS

ANSA

HYPERMESH

ANIMATOR

ABACUS

LS-DYNA

FLUENT

FE-SAFE

FEMFAT

MODEFRONTIER

STAR-CCM+

GAMBIT

VERTICALS WE CATER

AGRICULTURAL

EQUIPMENT

CONSTRUCTION

MACHINERY

FOREST

MINING

MATERIAL

HANDLING

SPM

CONSUMER, HEALTHCARE

& HI-TECH

PORTS

URBAN

TRANSPORTATION

MACHINE TOOLS

AUTOMOTIVE

RAILWAYS

SHIP DESIGN

AEROSPACE INTERIORS

METRO

CASE STUDIES

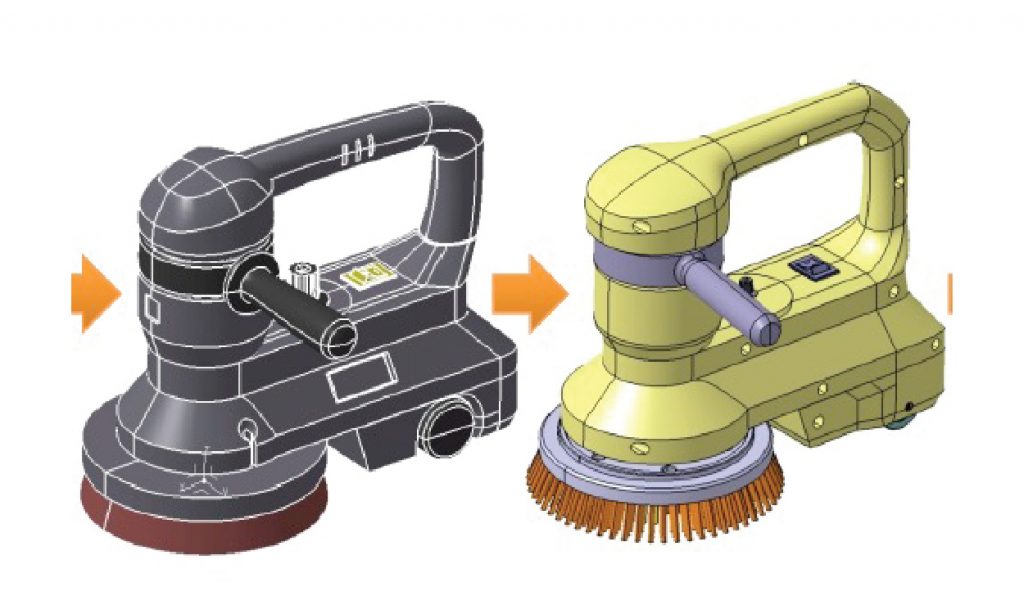

CASE 1

The client had an existing step cleaning equipment which they wanted to customise/indigenise for sale in India. In addition the new design was expected to overcome existing product limitations. A wish list was created and various concepts offered in line with these to the customer.

A new motor was selected after extensive supplier search, development, motor performance testing and validation. The client selected a combination of the two concepts. A prototype was developed and trials conducted. Based on the feedback from the trials some design changes were incorporated and a final industrial design developed (mature)

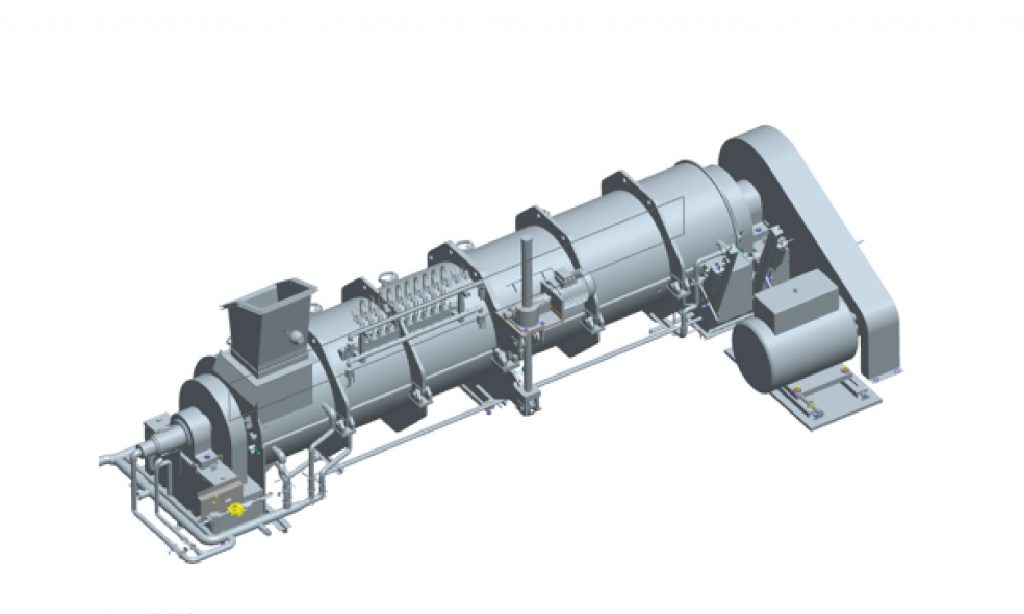

CASE 2

A glue blending machine was modified. Design modifications were implemented for the clients glue blending machine and design of all 46 variants were updated with respect to sub-assembly and parts. 3D model and manufacturing drawings and BOM were created. Updated and market competent machine version is developed which can increase client sales.

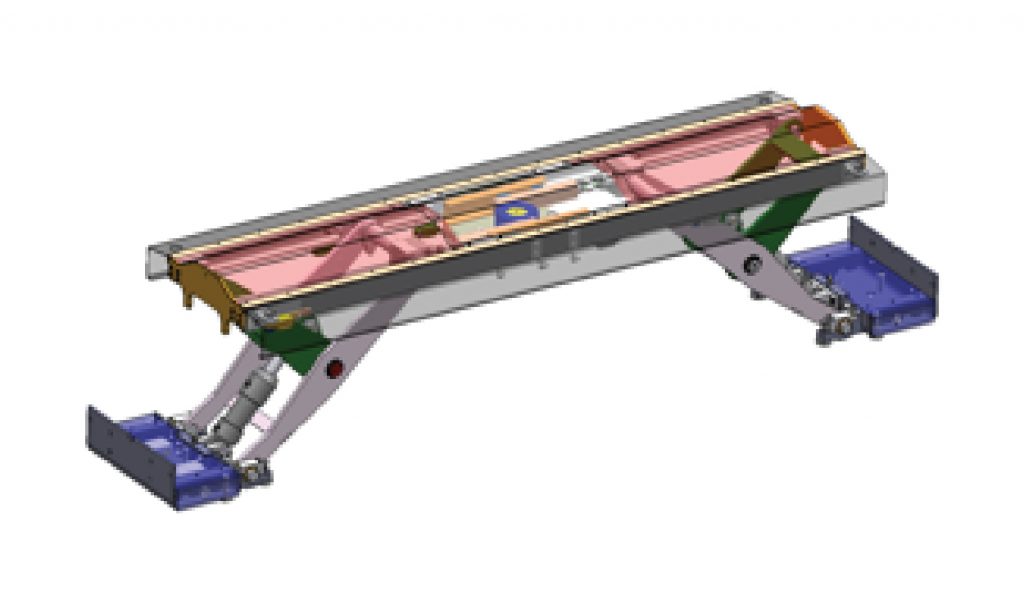

CASE 3

The client had an existing hydraulic scissor lift which had multiple problems leading to loss of production during roll change over. The client gave Tooltech the mandate to design a new scissor lift to avoid present issues and to be able to lift 5 tons corrugated roll carriage.

The new design added a hydraulic element to the mechanical synchronization, created a symmetric design, incorporated a Standard hydraulic cylinder and simplified various other element. All of these led to ease of maintenance, faster commissioning and reduced supplier dependency. Suitable for process line handedness

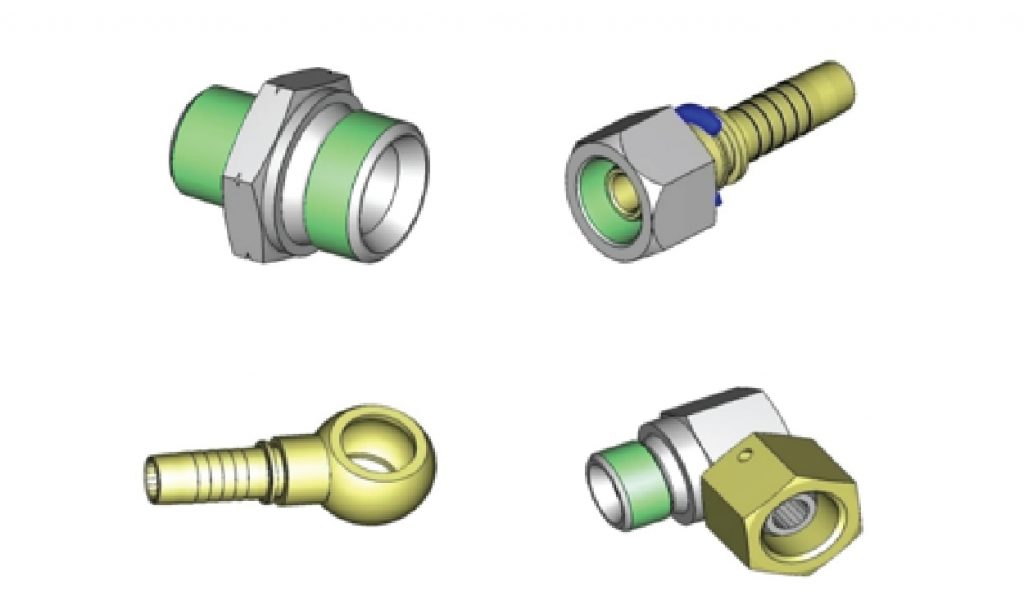

CASE 4

This hydraulics and lubrication systems manufacturer wanted to reduce their dependence on other suppliers for readymade hydraulic fittings & adaptors. At Tooltech, the design team reverse engineered the existing fittings and adaptors and created an entire set of manufacturing drawings with proper tolerances and GD&T Symbols for production use.